How to make an effective DFM report?

Design for Manufacturing (DFM) is a crucial link between product developers and mold manufacturers, ensuring designs are optimized for efficient production. A comprehensive DFM report is often the first step toward success in any mold-making project. The more potential problems you identify early, the less risk you face during the manufacturing process. A well-prepared DFM report not only highlights potential design flaws but also offers opportunities to enhance the process's efficiency, quality, and cost-effectiveness.

Understanding the Cost Implications: The 1:100:1000 Rule

The cost to fix a flaw escalates dramatically as a project progresses. Known as the 1:100:1000 rule, this principle shows that the cost to fix a design flaw increases from 1x in design, to 100x in development, and 1000x in production. A thorough DFM report helps mitigate these costs by identifying issues early on.

The Role of Experts in Creating a DFM Report

A DFM report is typically created by an injection molding expert or a manufacturing engineer. When designers or project managers fail to consider the manufacturing process, they may encounter numerous challenges, such as:

- A design flaw that makes it impossible to produce tools or parts.

- Inefficient processes that lead to increased manufacturing or production costs.

By addressing potential manufacturing difficulties proactively through a DFM report early in the product development phase, designers and engineers can create a more effective and economical injection molding process. This proactive approach helps prevent costly design alterations or adjustments once the tooling process has begun.

The Importance of Cross-Functional Collaboration in DFM

A well-executed DFM report involves collaboration among all parties, including engineers, designers, contract manufacturers, mold builders, and material suppliers. This cross-functional approach challenges the design from all angles—component, sub-system, system, and holistic levels—ensuring that the product is both cost-effective and optimized for production.

Essential Components of a DFM Report

An effective DFM report should include the following key components:

- Design Analysis: An assessment of the product design's suitability for injection molding, identifying features that may be challenging or impossible to mold effectively.

- Basic Tool Information: Details such as tool layout, cavities, and tool dimensions.

- Gate Location and Type Proposal: Recommendations for the most effective gate locations and types.

- Parting Line Definition: Suggestions for optimal parting line locations, including slider and lifter cores.

- Ejector Pin Location Proposal: Determining the best locations for ejector pins to ensure smooth part ejection.

- Wall Thickness Analysis: Ensuring uniform wall thickness to avoid potential defects like warping or sink marks.

- Draft Angles: Checking the design for appropriate draft angles to facilitate easy part ejection from the mold.

- Improvement Proposals: Identifying undercuts and complex features that may require additional design considerations or secondary operations.

- Rib Design: Assessing rib thickness and placement to reinforce the part without causing molding issues.

- Cooling Channels Proposal: Designing cooling channels to improve cycle times and prevent defects.

- Mold Flow Analysis: Simulating the injection molding process to predict potential issues such as air traps, weld lines, and flow imbalances.

Understanding the Limitations of DFM

While a DFM report is invaluable, it is only effective if designers utilize the data and take into account the toolmaker's suggestions. It is important to note that design decisions contribute to 75% of a product's manufacturing costs, while only 25% are related to production decisions. Therefore, ensuring sufficient time for DFM during the design process is crucial. Rushed DFM reports can lead to failures, delays, and significantly higher expenses down the line.

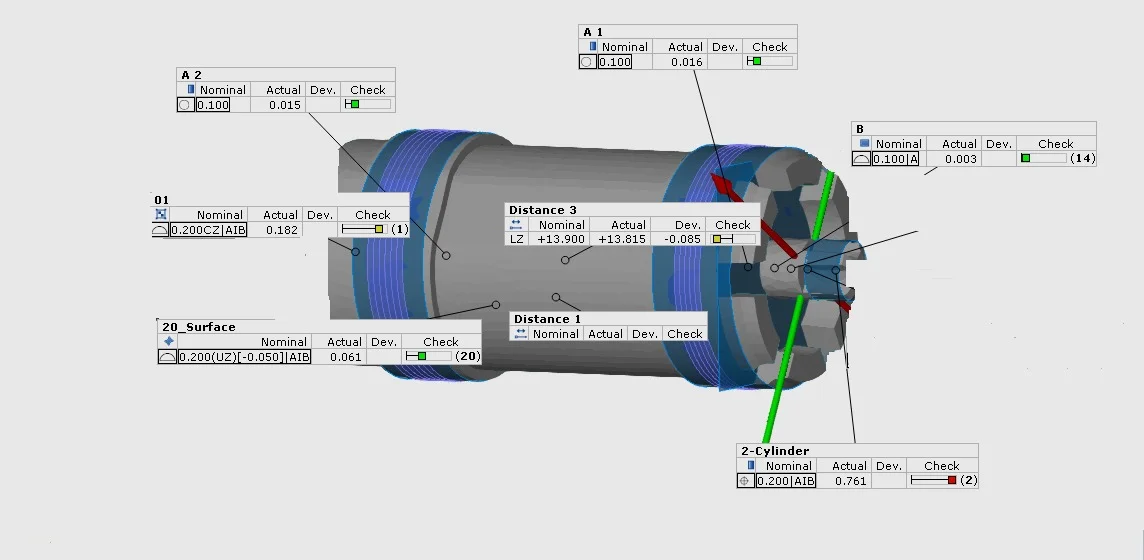

The Role of Virtual Measurements in DFM

Virtual measurements play a crucial role in the final chapter of the DFM report. These measurements involve comparing a 3D deformed model, generated from Moldflow analysis, with the original CAD data. This process, which uses tools like GOM Inspect, allows for a detailed inspection of potential discrepancies, helping to ensure the final product meets all design specifications.

For more detailed insights on virtual measurements, you can read our next post on Virtual Measurements or click here.

Conclusion: The Impact of an Effective DFM Report

Creating an effective DFM report is critical for reducing risks, minimizing costs, and ensuring the manufacturability of a product. By involving cross-functional teams, conducting thorough design and tooling analyses, and leveraging advanced tools like mold flow simulations, you can produce a DFM report that significantly enhances the efficiency and success of your mold manufacturing projects.

Get Expert Assistance for Your DFM Report

If you have a project that requires a comprehensive DFM report, contact us today. Our team of experts is ready to help you streamline your manufacturing process and bring your designs to life efficiently and cost-effectively.

For more information, feel free to send us your questions at info@dfmconsultation.uk.