Injection molding simulation – Moldflow – additional cost or key to flawless manufacturing?

Injection molding simulation, particularly using Moldflow, is a critical tool for ensuring flawless manufacturing. At DFM CONSULTING, we collaborate closely with skilled toolmakers and innovative product designers, each responsible for their respective areas of expertise. When applied correctly, Moldflow serves as a powerful instrument for evaluating feasibility and addressing potential challenges early in the process. Conducting a thorough injection molding simulation during the inquiry phase is crucial for identifying issues such as warpage and ensuring that all aspects of the design are optimized before production begins.

The Importance of Early Injection Molding Simulation

To achieve a successful manufacturing process, it's essential for part designers to engage in injection molding simulation early in the design phase. This proactive approach allows for the identification and resolution of potential issues like part deformation or warpage, which could compromise the final product's quality. By incorporating Moldflow analysis into the initial stages, the feasibility of producing a part can be accurately assessed, reducing the risk of costly errors later on.

Accurate Input Equals Accurate Results

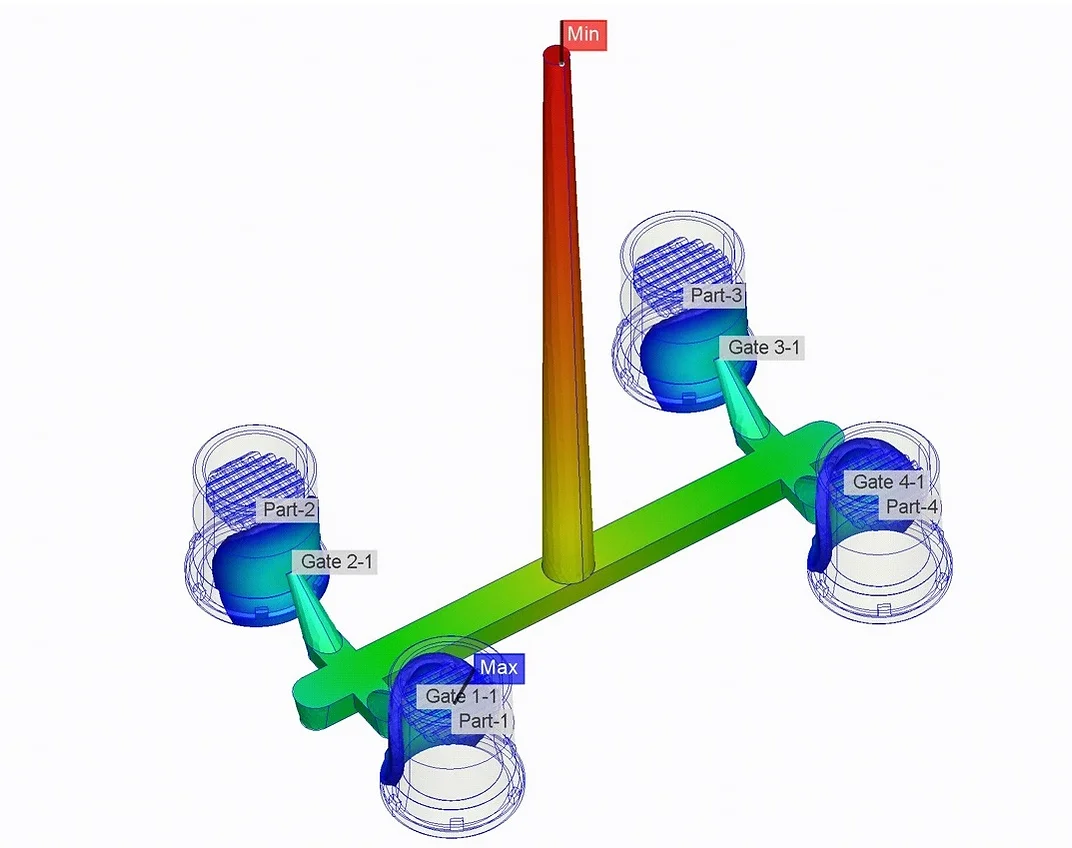

The accuracy of your Moldflow analysis is directly tied to the quality of the input parameters. A comprehensive approach is necessary to ensure realistic and reliable results from your injection molding simulation. Key areas to focus on include gate and runner design, cooling systems, and parting lines. By meticulously analyzing these aspects, the Moldflow analysis can guide you toward optimized and efficient manufacturing processes, ultimately leading to a better-quality product.

Cooling Analysis: A Critical Step Before Predicting Warpage

Performing a Cooling Analysis before calculating part warpage is crucial. If you skip this step, you might assume that you have a perfectly uniform mold wall temperature across all surfaces—a rare occurrence in real-world scenarios. More often, there is a non-uniform temperature distribution, leading to unbalanced cooling. This imbalance causes asymmetric tension-compression patterns across the part, resulting in warpage. Conducting a detailed Cooling Analysis ensures that the Moldflow results are as accurate as possible, minimizing potential defects in the final product.

When to Perform Injection Molding Simulation - Moldflow?

The best time to conduct Moldflow analysis is during the inquiry phase, alongside the Design for Manufacturing (DFM) report. These analyses are critical for ensuring the success of the manufacturing process. The most valuable insights provided by injection molding simulation include:

- Flow Information: Identifying short shots, weld lines, and air traps.

- Pack Information: Assessing sink marks and gate freeze times.

- Warpage Information: Predicting dimensional stability and part deformation.

These insights allow for the optimization of the DFM report, including adjustments to gate locations, runner systems, and more. After obtaining the latest revisions, a virtual measurement of the deformed part can be conducted. This step helps determine whether the warpage remains within the specified tolerances, allowing for necessary adjustments before production begins.

Common Failures in Tool Manufacturing and Part Production

Throughout our experience, we've encountered several common issues in tool manufacturing and part production, which can often be mitigated through proper injection molding simulation:

- Visible Sink Marks: Surface imperfections that compromise part aesthetics and functionality.

- Incorrect Draft Angles: Leading to ejection problems during molding.

- Surface Structure Issues: Resulting in parts that do not meet quality standards.

- Warpage: Parts that do not meet dimensional requirements.

- Burrs/Flashes: Excess material in critical areas affecting part integrity.

Finalizing the Tool Design with Moldflow

Before tool construction begins, it's essential to update the DFM report and conduct a new Moldflow analysis. This step ensures that any changes in the part design or material are accounted for, leading to accurate predictions and minimizing uncertainties in the manufacturing process. With the final tool design and precise input data, the Moldflow analysis provides highly accurate results, offering valuable insights and reducing the risks associated with the production process.

How DFM Consulting Can Assist You

Whether you're a tool producer, tool manufacturer, or part designer, DFM CONSULTING is here to assist. Our expertise in injection molding simulation and Moldflow analysis can help you streamline your manufacturing process, ensuring that your products meet the highest standards of quality. For more information or to get started, please contact us at info@dfmconsulting.uk.